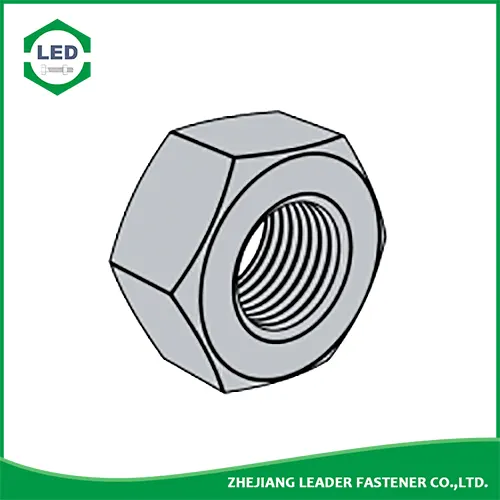

DIN 2510 Hex Nut

Leader-Fastener® is a manufacturer and distributor of DIN 2510 Hex Nut. We have a complete line of service from having invested in production plants, export department and to having a quality control team and center to meet your requirements. We regard quality as the life of the company. We persist in good quality as the first policy and have established a set of quality control and inspection system according to the international standard. We have carried out ISO9001 Quality Guarantee System in every course of production, transportation and selling. We do hope we could be your partner in business by topping quality, knight service and competitive price in the near future and be your friends as well.

Send Inquiry PDF DownLoad

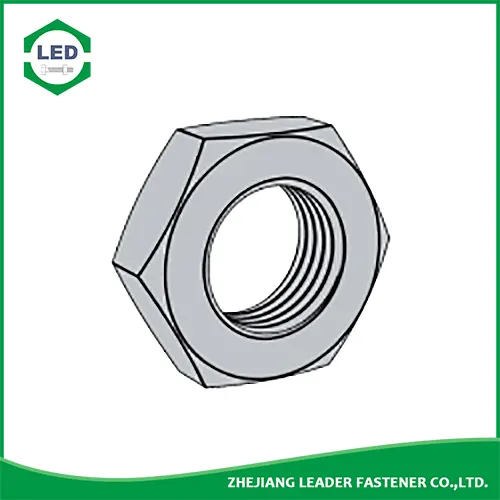

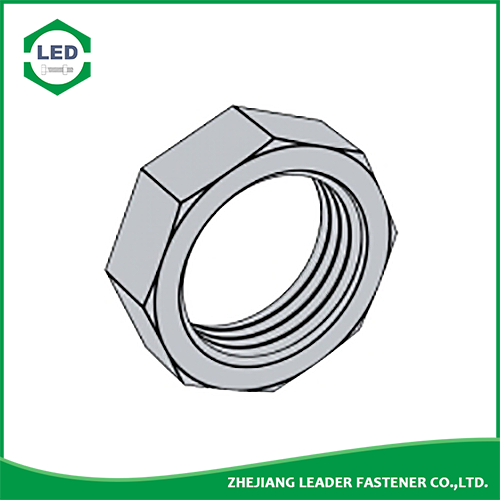

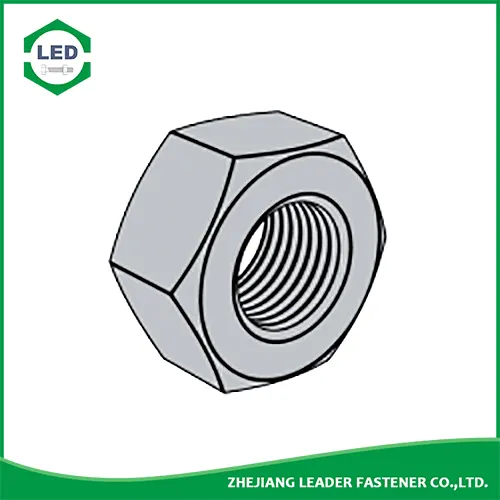

NF is most common shape of DIN 2510 nuts, produced by forging or machining from bar. Forged nuts have only hardness in certificate, machined have full mechanical results.

Product Specification of Leader-Fastener® DIN 2510 Hex Nut

Material: Carbon steel, Stainless steel, Alloy Steel, Brass.

Finishment: Black, Zinc Plated, Zinc Yellow, HDG, Phosphate, DACROMET, Geomet, Magin, Ruspert, Teflon, etc.

Leader-Fastener® DIN 2510-5 (NF / TF) - 1971 Bolted Connections With Reduced Shank Hexagon Nuts

|

Thread Size D |

M12 | M16 | M20 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | |||

| P | Pitch | 1.75 | 2 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 | ||

| d2 | 21 | 26 | 31 | 35 | 40 | 45 | 49 | 53.5 | 58.5 | 63.5 | 68.5 | 73.5 | 78.5 | 83.5 | |||

| d3 | 14.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 | 39.5 | 42.5 | 45.5 | 49.5 | 53.5 | 57.5 | 63 | |||

| e | min | mg | 23.91 | 29.56 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 77.74 | 83.39 | 89.04 | 94.47 | |

| m | 24.49 | 30.14 | 35.72 | 39.98 | 45.63 | 51.28 | 55.8 | 61.31 | 66.96 | 72.61 | 78.26 | 83.91 | 89.56 | 95.07 | |||

| m | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | 52 | 56 | |||

| s | 22 | 27 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | |||

| t | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | |||

| per 1000 units≈kg | 31 | 52 | 86 | 124 | 181 | 260 | 330 | 425 | 560 | 705 | 900 | 1120 | 1340 | 1590 | |||

|

Thread Size D |

M64 | M72 | M80 | M90 | M100 | M110 | (M120) | M125 | M140 | (M150) | M160 | (M170) | M180 | |||

| P | Pitch | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d2 | 93.5 | 103.5 | 113.5 | 128 | 143 | 153 | 168 | 178 | 198 | 208 | 218 | 228 | 253 | |||

| d3 | 71 | 79 | 87 | 97 | 107 | 119 | 129 | 134 | 149 | 159 | 174 | 180 | 196 | |||

| e | min | mg | 105.77 | 117.07 | 128.37 | 145.09 | 162.04 | 173.34 | 190.3 | 202.27 | 223.91 | 235.21 | - | - | - | |

| m | 106.37 | 117.67 | 129.34 | 145.77 | 162.74 | 174.02 | 191.49 | 201.59 | 224.7 | 236 | 247.3 | 258.6 | 286.68 | |||

| m | 64 | 72 | 80 | 90 | 100 | 110 | 120 | 125 | 140 | 150 | 160 | 170 | 180 | |||

| s | 95 | 105 | 115 | 130 | 145 | 155 | 170 | 180 | 200 | 210 | 220 | 230 | 255 | |||

| t | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |||

| per 1000 units≈kg | 2230 | 2980 | 3850 | 5550 | 7700 | 9250 | 13100 | 14900 | 20100 | 22800 | 26000 | 29400 | 41000 | |||

①,Technical delivery conditions and materials according to DIN 267 sheet 13 。made of 24CrMo5